‘ALLATINI’ BISCUIT FACTORY, AT CHALKIS

Images7

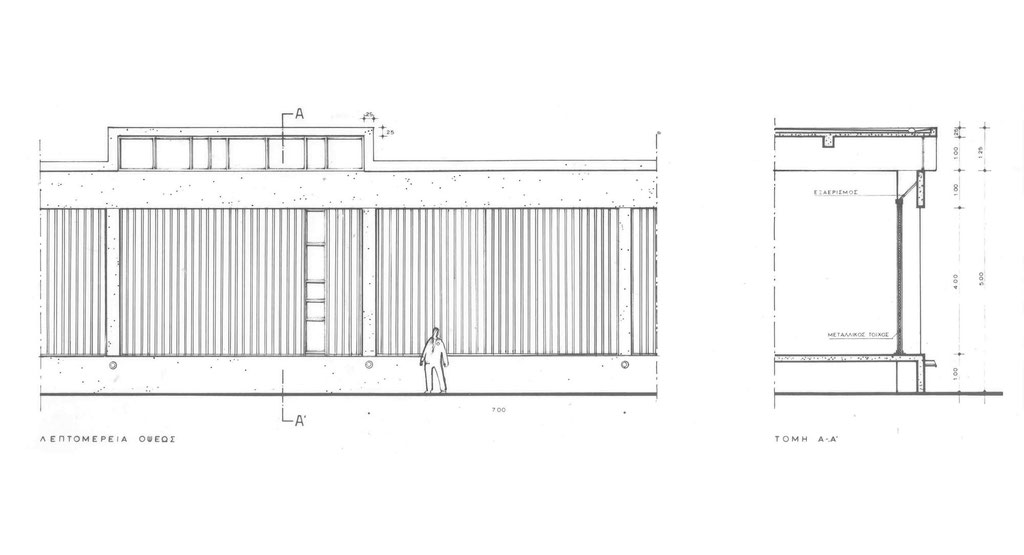

View:

Photos

Designs

Illustrations

Description

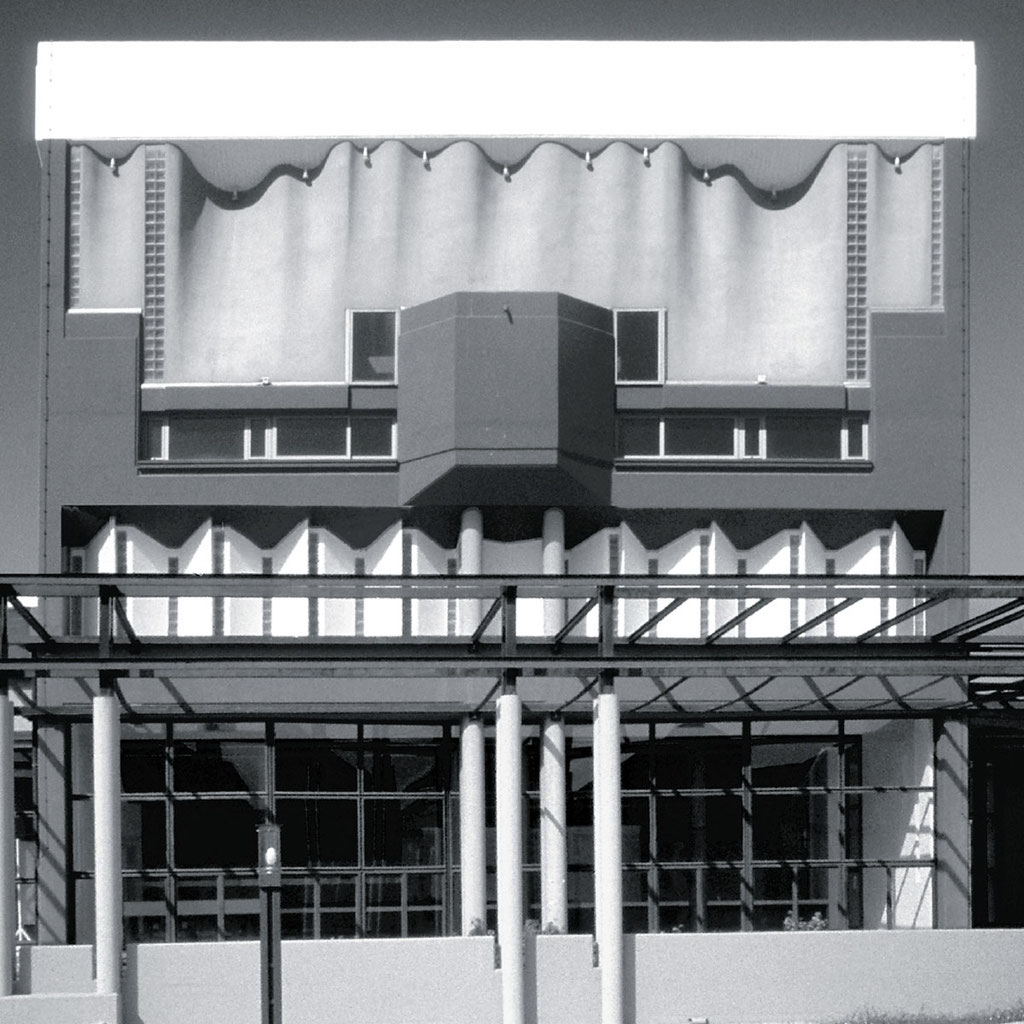

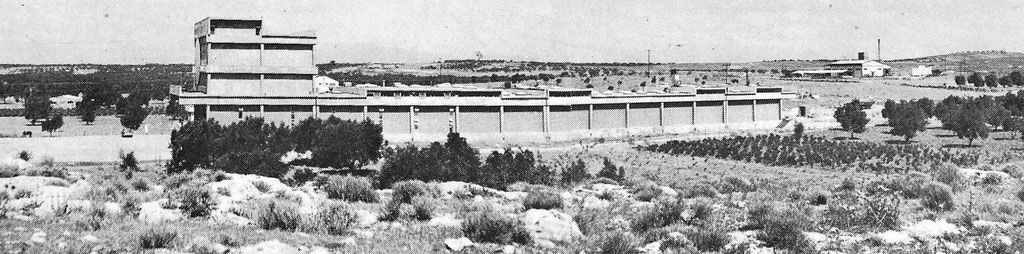

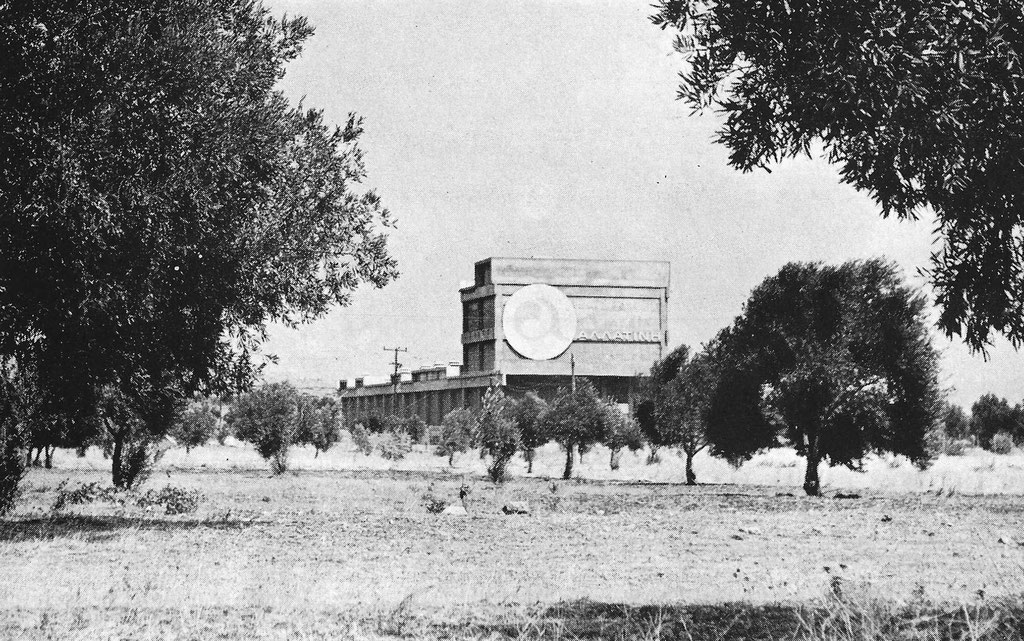

The first unit built is a vertical tower plus the main production building, with input and output platforms at each end. Αn elevator moves the basic materials up the tower. Floor is stored on the top floor, from where it moves down while being treated, mixed, turned into dough and shaped into biscuits, which are baked and cooled on the ground floor, then packed and stored for delivery. Waffles are produced on a parallel line. Services are Ιοcated in the main production building; dressing-rooms and personnel restaurant occupy a separate building. The load-bearing structure is of pre-stressed concrete on a 7.50 m. by 15.00 m. module. All walls are movable, with an insulating core of glass-wool panels and metal frames. Exterior walls are galvanised metal sheets and interior ones asbestos-cement sheets. Mosaic floors have aluminum stripping every 2.50 m. Ventilation is either natural or mechanical, depending on needs, while other spaces are air-conditioned. Natural indirect lighting is ensured throughout with a peripheral 450 glass strip and overhead plastic skylights. The factory went into production in May 1967. Future expansion estimates call for a four-fold increase in buildings and a ten-fold increase in present production figures.

Civil engineer N. Arachovitis. Prestressed concrete Morandi. Mechanical engineers Werner & Pfleiderer. Landscaping R. & M. Adams.

Text from the magazine: «architecture in Greece» Νο 2 , 1968.